language

中国

韩国

韩国

韩国

韩国

韩国

激光切管机 可以更快的进行复杂的切割

- 发布时间:2020-05-02 16:43

- 访问量:4

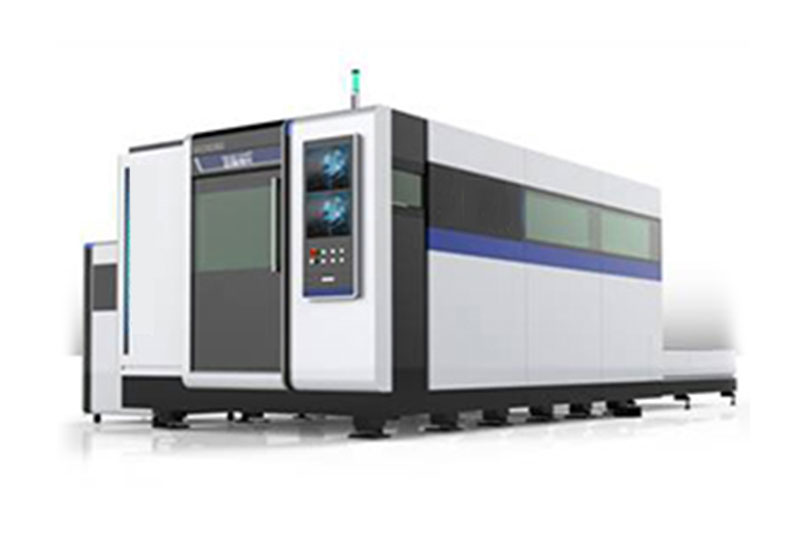

激光切管机 可以更快的进行复杂的切割

【概要描述】激光切管机借用了计算机辅助设计软件进行图形设计,并导入了切割机操作系统以执行自动切割,从而大程度地提高了制造项目的速度。通常,操作系统中包含一个数据库,关键信息包括管的材料类型,厚度和几何形状。所以激光切管机可以更快的进行复杂的切割,并提高工作效率。

- 发布时间:2020-05-02 16:43

- 访问量:4

详情

激光切管机可以无缝切割金属和其他材料。对机器编程后,该机器可广泛用于自定义切割操作。激光切管机的基础是激光束。激光按波长区分。因为它们可以承载大量信息,所以没有电磁干扰,也没有信号泄漏,因此它们经常在通信工程中使用。当应用于金属切削时,它具有高能量密度和窄光束的优点。

使用激光切管机的好处之一是,它可以比其他机器更快地进行复杂的切割。例如,在各种形状和尺寸的管道上钻孔并切割各种形状。另外,激光切管机可以提供良好的切割截面,并且后续的加工(例如焊接)不需要二次处理,这也适用于切割薄壁和厚壁管道。使激光切管机真正与众不同的是切割的准确性。由于现代激光切割机的改进,涉及小直径管道的工业制造应用已大大加速。

激光切管机借用了计算机辅助设计软件进行图形设计,并导入了切割机操作系统以执行自动切割,从而大程度地提高了制造项目的速度。通常,操作系统中包含一个数据库,关键信息包括管的材料类型,厚度和几何形状。所以激光切管机可以更快的进行复杂的切割,并提高工作效率。

关键词:

上一个:

手持式激光焊接机的优缺点介绍

下一个:

激光切管机的自动排版功能优势所在

上一个:

手持式激光焊接机的优缺点介绍

下一个:

激光切管机的自动排版功能优势所在

什么是地轨式激光切割机?有什么优势?

激光切割头的QBH和QCS接口的区别

优顺万瓦级激光切割机加工厚板材的优势

Copyright © 苏州优顺激光装备有限公司

Copyright © 苏州优顺激光装备有限公司 苏ICP备19073043号-1 SEO导航

官方微信