激光切管机的安全操作规范

- 发布时间:2020-05-14 17:17

- 访问量:6

激光切管机的安全操作规范

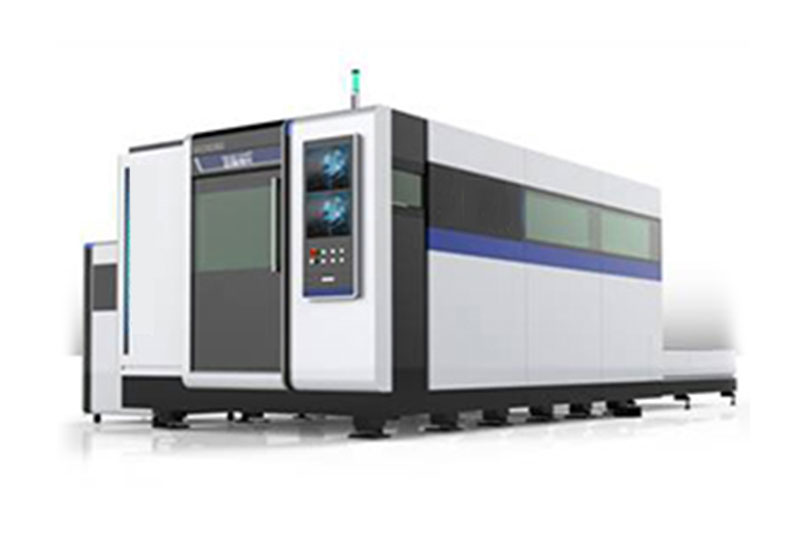

【概要描述】激光切管机的安全操作规范,苏州优顺激光装备有限公司是一家以激光技术为核心的高新技术型企业。公司专注于激光加工成套装备的研发丶制造和销售,包括大小功率激光切割机、激光焊接机、激光光刀模、多功能激光加工设备,为客户提供个性化和专业化的激光加工系统解决方案。主营业务及产品有激光设备改造、激光设备升级、激光器维修、激光设备定制、手持焊接机、激光切管机、激光焊接机、激光切割机、激光镜片等,一直秉承“客户第一

- 发布时间:2020-05-14 17:17

- 访问量:6

激光切管机安全运行过程分析:

1.遵守通用激光切管机的安全操作规则。严格按照激光启动程序启动激光。

2.必须对操作员进行培训,熟悉激光切管机的结构和性能,并掌握操作系统的知识。

3.根据需要佩戴劳动保护用品,并在激光束附近佩戴符合规定的防护眼镜。

4.在弄清是否可以用激光辐照或加热材料之前,请勿对其进行处理,以免产生烟雾和蒸汽的潜在危险。

5.激光切管机也可以说是激光雕刻机启动时,操作员不得离开立柱或让他人等待。 如果确实有必要离开,则应停止机器或关闭电源开关。

6.将灭火器放在容易拿到的地方;不加工时关闭激光器或快门;请勿将纸,布或其他易燃材料放在未保护的激光束附近。

7.如果在此过程中发现激光切管机异常,应立即将其停止,并消除故障或及时报告主管。

8.保持激光器,床和周围区域整洁,有序且无油污。 工件,板材和废料按照规定进行堆放。

9.维护时,请遵守高压安全规定。每个操作都必须按照规定和程序进行。

10.激光切管机开启机器后,应在X和Y方向上以低速手动启动机床,以检查是否有异常情况。

11.输入新的工件程序后,应进行试运行并检查其运行状态。

12.激光切管机工作时,请注意观察机床的操作,以防止切割机超出有效行程或由于两台机器的碰撞而引起的碰撞。

全面详解手持焊专用激光器的应用工艺参数,为您解决焊接难题提供有力支持

什么是地轨式激光切割机?有什么优势?

激光切割头的QBH和QCS接口的区别

Copyright © 苏州优顺激光装备有限公司

Copyright © 苏州优顺激光装备有限公司 苏ICP备19073043号-1 SEO导航

官方微信